WELCOME TO

TECHNI WATERJET®

Materials You Can Cut

Stone

Metal

Fibreglass

Glass

Plastic

Cardboard/Paper

Composites

Insulation/HVAC

PFoodlastic

Other

Get ahead in your industry with TECHNI Waterjet® your go-to source for top-of-the-line abrasive Waterjet machinery and cutting-edge technology. With over three decades of experience, our dedicated team of engineers continually pushes the boundaries of high-pressure abrasive waterjet cutting solutions.

At TECHNI Waterjet®, we prioritize collaboration with your business to understand your unique challenges, tailoring our cutting-edge water jet cutters to suit your needs perfectly.

Count on our expert sales team to provide the guidance and equipment necessary for you to maximize your ROI and achieve success in your endeavors. Choose TECHNI Waterjet® for unmatched precision and reliability in waterjet cutting technology.

Benefits of TEKNI Series

Waterjet Machines

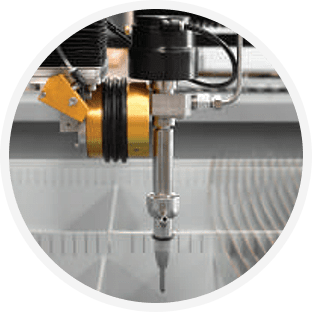

Powerful waterjet nozzle cuts parts from stainless steel, granite, plastic and more.

Advanced technology enhances task time management.

Superior cutting performance reduces finishing time.

Remote motion control systems facilitate concurrent task management.

Our waterjet systems handle multiple materials without tooling changes.

No heat zones, no dust or debris, no fumes, no toxic gases, quiet operation

AWARDS

Award For Innovation

Manufacturing Excellence

Innovation Excellence

Business Innovation

STANDARD FEATURES

TEKNI Series

REMOTE CONTROL PENDANT

The Manual Pulse Generator (MPG) facilitates manual winding in both forward and backward directions along a cutting path. This capability empowers operators to pinpoint the precise position along the path to resume cutting after a pause or accurately locate a pre-cut part.

BREAK AWAY HEAD

If the cutting head accidentally collides with a clamp, fixture, workpiece edge, or protruding part, the Break Away Head system will swiftly detect the impact and halt the machine automatically

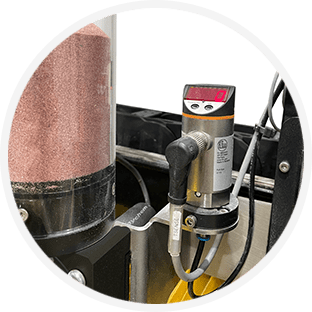

TECH SENSE

Our latest variable abrasive feeder automatically adjusts garnet supply to the cutting head through software control, particularly useful during low-pressure piercing. Moreover, the Tech-Sense™ Monitoring System facilitates seamless unattended operation. Following any interruptions, resuming the cutting program is effortlessly accomplished.

WATER RAISE & LOWER

Our submerged cutting feature offers automatic water Raise/Lower functionality with just the push of a button. The tanks are equipped with airtight welds forming an air chamber that utilizes standard shop air pressure. There’s no need for additional moving parts; an on/off solenoid valve facilitates water level adjustments within seconds.

SERVO Z AXIS

Our Z axis comes with programmable capabilities that facilitate auto height position recall, along with innovative laser terrain mapping and edge location optics. These features ensure precise and consistent cutting depths while enhancing visibility and accuracy, making your cutting tasks more efficient and reliable.

AFTER PURCHASE TRAINING & MACHINE SUPPORT

Is Our Priority

We are among

Global Leaders of

Waterjet Technology

Latest Blog Posts

Mastering Abrasive Machining: A Comprehensive Guide to Precision Manufacturing

Welcome to our definitive guide on abrasive machining, where we delve deep into this indispensable…

Speak To A Specialist

Please fill out the form below with your details. One of our Waterjet specialists will be in contact with your shortly.